Clamp Manipulators

Fazzini Meccanica designed various models of Clamp Manipulator. Here a brief description of two of the most important ones.

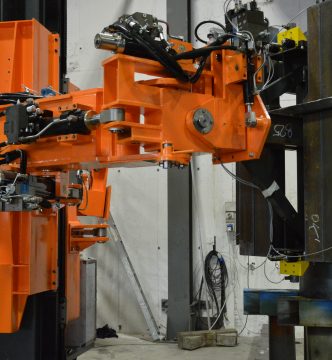

The first manipulator was installed on board the J-Lay tower of the SAIPEM7000 pipe lay vessel used to apply the coating process on the pipe joint during offshore pipe lay operations. The working station is mainly made up of three working manipulators which position on the pipe 3 clamps working for the different coating processes (blasting, heat & coat and injection molding) and performed in a controlled sequence of actions on the pipe joint and relevant handling system.

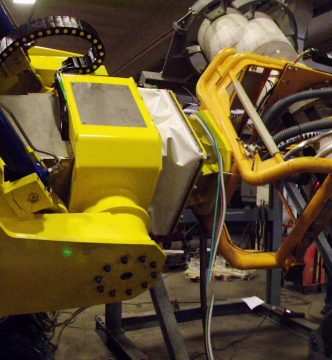

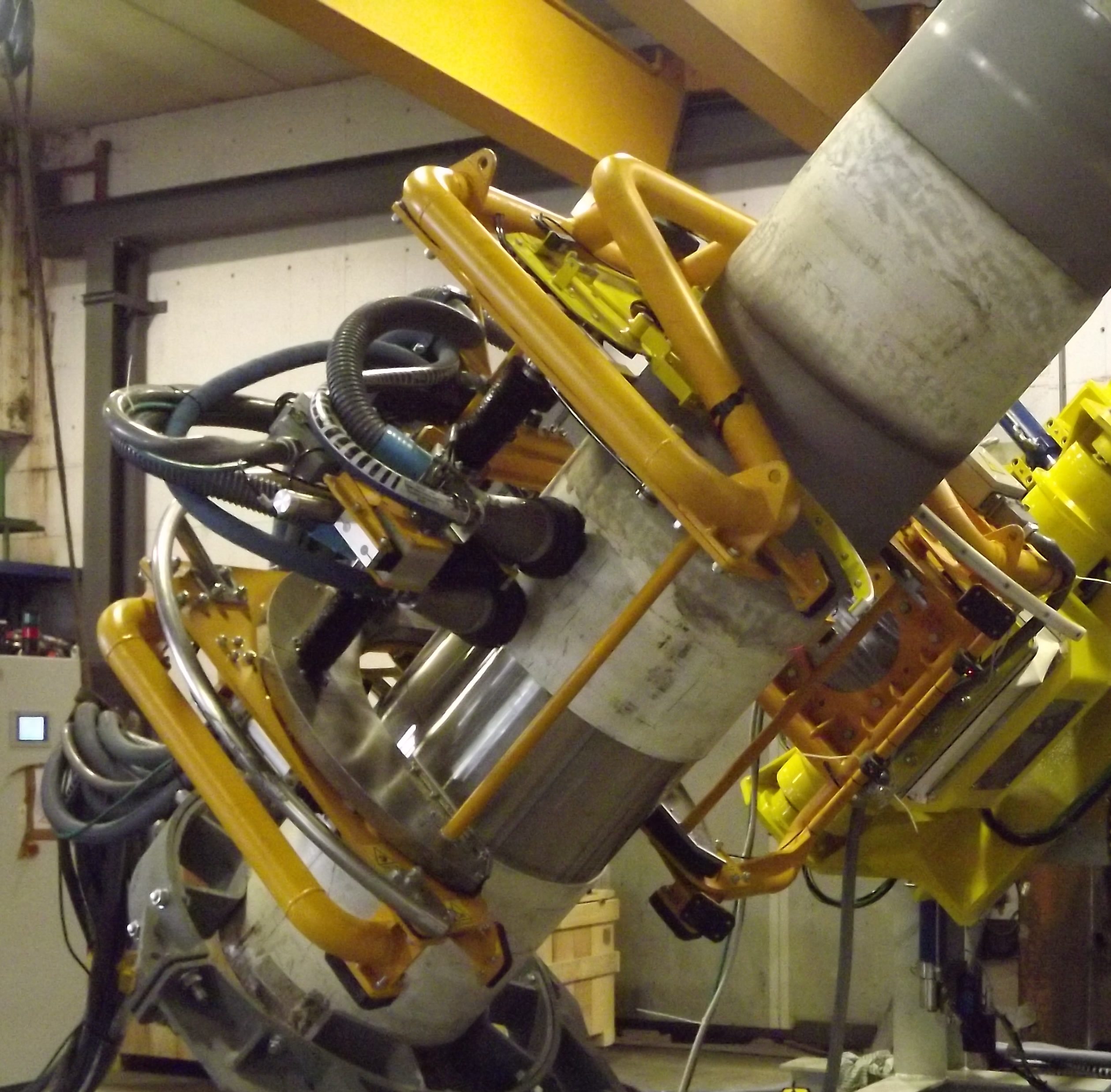

The second type of manipulator is an onboard device installed on the SAIPEM ships FDS and FDS2, whose task is the positioning of the Heat and Coat Clamp from the resting site to the working position onto the pipe to be laid.The blasting clamp is a special machine providing the sand blasting of the joint of the pipe to be laid, before anticorrosion coating and joint filling. It has a cylindrical shape and can be opened in two halves for clamping on the pipe to be laid.