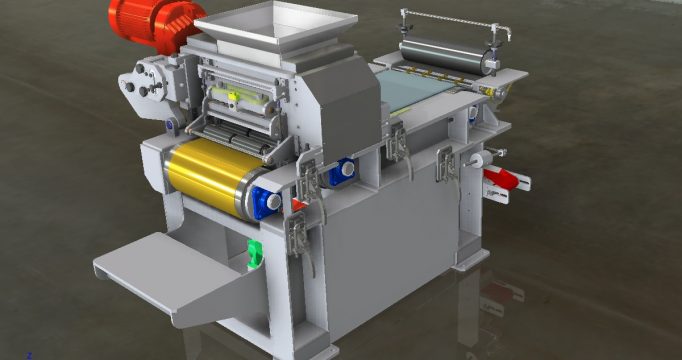

Double Side Pasting Machine

This pasting machine is a real innovation in the sector because it pastes the grids on both sides in one operation, and for that reason it has been patented by the constructor. The project realization has been a great challenge because Fazzini Meccanica has been in charge of the design of the machine and the prototype development working directly with proper technicians in the customer production facility.

Technical characteristics: The machine pastes on both sides lead alloy grids up to 4 mm thick. Two belts are fitted on the machine. The first polyester belt introduces the grids under the hopper, the second, with very hard structure, is fitted in the finishing section to assure a perfect calibration of the product. A couple of motorized rollers are fitted in the central zone to ensure the paste delivery in the lower part of the plates.

A 7.5 Kw motor with inverter is fitted to move both the belts and the feeder. The new conception hopper is divided in two parts, in the first the paste delivery is done, in the second the excess paste is taken away and there is the thickness calibration of the plate. The hopper hoisting is assured by a pneumatic cylinder. The finishing rubber rollers are fitted with water nozzles that are fed with a solenoid valve. Once the machine is stopped the water delivery is also closed. A sensor stops the machine if there are not grids in the feeder or if there is a double grid in the feeder. The belt change is very easy and quick and there is centralized greasing unit.